Protect your people, your equipment, and your bottom line.

Arc Flash is a Serious Risk with Potentially Catastrophic Consequences

Ensuring worker safety and meeting the challenges of arc flash safety requirements can be a demanding task. An arc flash analysis from AMG can help you address these challenges, ultimately enhancing the safety and productivity of your facility.

AMG has the qualified engineers and technology necessary to provide a range of arc flash related services that can satisfy regulatory requirements and provide additional benefits to the operation of your business.

What is Arc Flash?

Arc flash is a sudden, explosive, unintended release of electrical energy caused by a fault or short circuit in an electrical system. This phenomenon generates extreme heat and light, and may include dangerous decibel levels, a concussive pressure wave, toxic fumes, and flying debris that can include molten or vaporized metal.

Arc flash events are often over very quickly but can be extremely dangerous, posing significant hazard to individuals working on or near electrical equipment. Arc flash events can lead to severe injuries or fatalities and can critically damage equipment and facilities. It is important to assess and mitigate arc flash risks through comprehensive analysis, safety measures, and protective equipment.

What is Arc Flash Analysis?

Arc flash analysis, study, or hazard analysis, is a comprehensive assessment of an electrical system to evaluate the potential hazards and risks associated with arc flash incidents. It involves the calculation of incident energy, determination of arc flash boundaries, and the recommendation of proper Personal Protective Equipment (PPE) and safety measures to protect personnel. The analysis considers various factors, including equipment, electrical parameters, and system configuration to provide precise insights into arc flash hazards. The analysis may include field data collection, electrical system modeling, short-circuit and coordination studies, and the creation of arc flash labels. It is a critical step in ensuring the safety of individuals working with or around electrical equipment, as it helps prevent accidents, injuries, and damage while also ensuring compliance with regulatory standards like NFPA 70E and OSHA. The analysis identifies incident energy exposure for workers, flash protection boundaries, appropriate working distances, and required PPE. Incident energy is the amount of energy impressed on a surface, a certain distance from the source, generated during an arc flash event. Incident energy is measured in calories per centimeter squared (cal/cm2) or joules per centimeter squared (j/cm2).

An arc flash analysis should only be carried out by a licensed Professional Engineer (PE) and requires specialized software, dedicated time and resources, and a commitment to follow through on requirements and recommendations.

What Do We Offer?

Do I Need an Arc Flash Analysis?

All electrical equipment and installations carry some level of risk, especially those that are maintained or operated while energized. Any business with a power system and is subject to NFPA 70E and OSHA standards may need an arc flash analysis to maintain compliance. OSHA requires the identification and labeling of electrical hazards and views the NFPA 70E “Standards for Electrical Safety in the Workplace” as the standard for addressing electrical hazards. At a minimum, an arc flash analysis is required every five years. Significant upgrades or modifications to your electrical system also warrant an arc flash analysis to evaluate the impact on safety.

Ensuring the safety of personnel and compliance with regulations makes an arc flash analysis a vital component of any electrical risk management strategy.

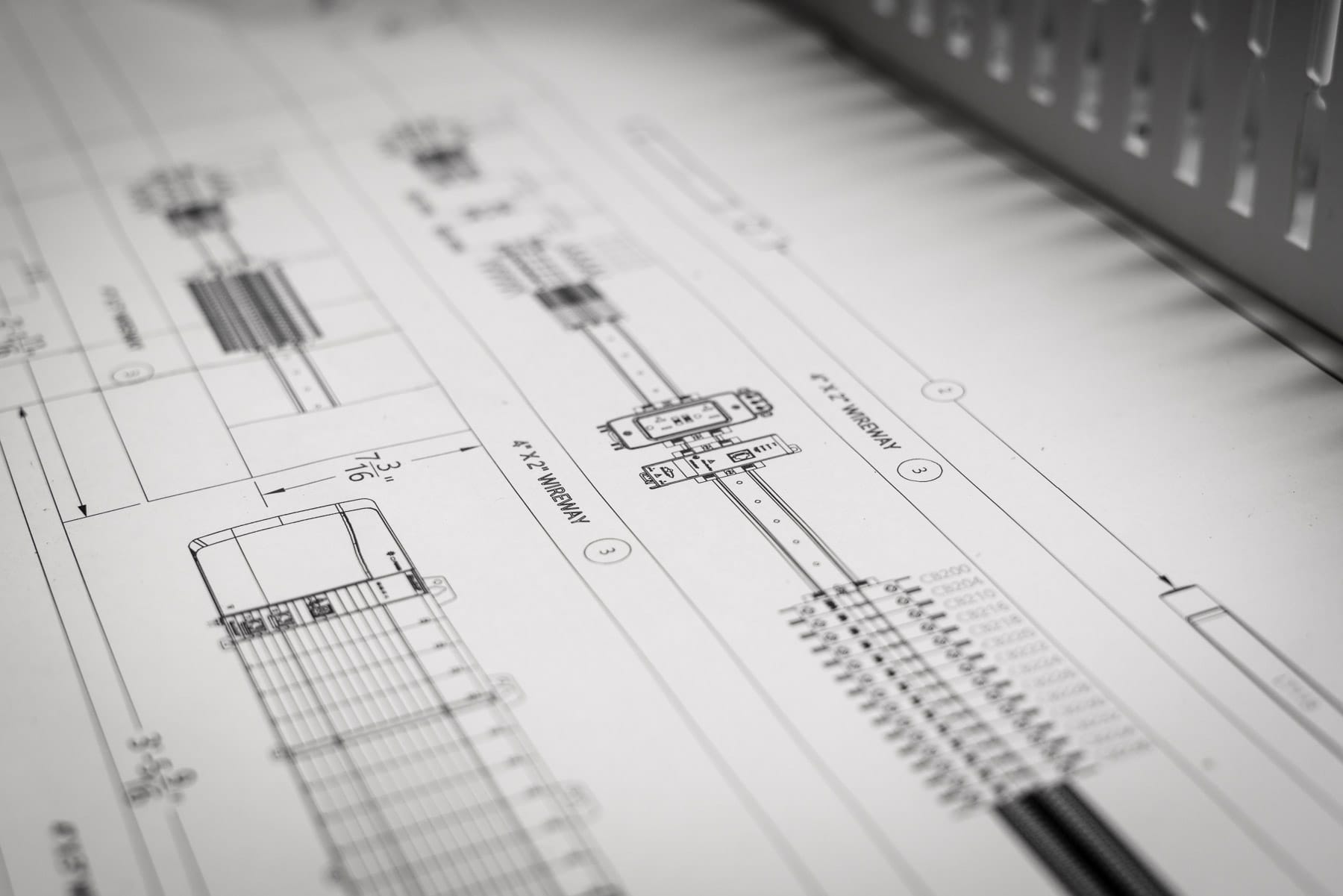

Categories and Types of Custom Control Panels We Provide

Custom Control Panels

Don’t Wait for a Problem!

We are able to offer any of our services requiring a licensed professional engineer (PE) in the following states. Certain other services may be available nationwide.

- Florida

- Illinois

- Indiana

- Iowa

- Kentucky

- Michigan

- Nebraska

- North Carolina

- Ohio

- Oregon

- Tennessee

- Texas

- Vermont

- Wisconsin