We Engineer for

Uptime & Performance

Our Mechanical

Team’s Strengths

Every facility has mechanical components that power processing operations. Engineering is crucial to ensure proper sizing specifications and system design.

Our team of mechanical engineers and designers leverage their “out of the box” creativity to develop and implement cost effective, intuitive, robust solutions for mechanical challenges. From calculating the pressure drop for a pneumatic convey system, to analyzing the stress in an evaporator vapor duct, we have the skill set, knowledge base, and experience to fill your mechanical needs, large or small.

Whether your project involves a failure analysis of a mechanical component, or new component design, engineering a new dust collection system or resolving problems in an existing one, evaluating the stresses in an existing steam line or designing a new one for long term, trouble free lifecycle, we offer these and more services to solve your challenges.

Mechanical Engineering Services

Material Handling System Design

- Pneumatic Conveying (Dense, Dilute, Positive, and Negative)

- Mechanical Conveying

- Weighing, Feeding, and Blending

- Bulk Receiving and Loadout (Truck and Rail), Storage, Reclaim, Silos, Bins, etc.

- Chutes, Spouts, and Ductwork

-

Utility System Design

-

- Boilers, Steam and Condensate Systems

- Compressed Air Systems

- Cooling Tower and Chilled Water Systems

- Vacuum Systems

-

- Production, Manufacturing, and Process Facility Layout

- Process Aspiration & Dust Collection System Design

- Dry and Liquid Storage and Handling Facility Design

Industrial Building Ventilation and HVAC Design

Mechanical Design and Analysis

- Specialty Machine and Mechanism Analysis, Design, and Improvement

- Finite Element Analysis

- Thermal Stress Analysis

- Piping Stress Analysis

- Hydraulic Power Units, Circuit and Component Specification, Analysis, and Design

See Other Core Disciplines

Professional Associations We Belong To

Ready to get Started?

Technology/Software Tools We Use

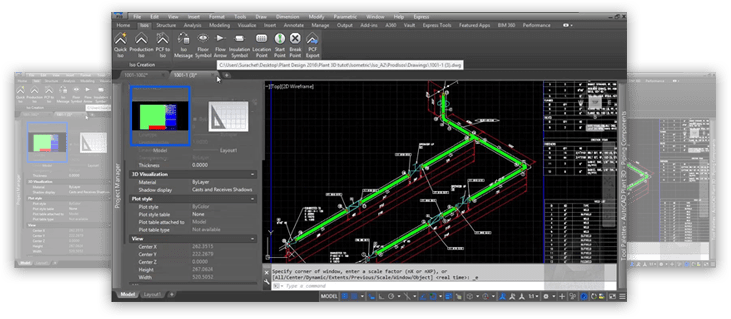

- AutoDesk AutoCAD® – 2D / 3D CAD Design Software

- AutoDesk AutoCAD Plant 3D® – 3D Intelligent Piping & P&ID design Software

- AutoDesk AutoCAD Inventor® – Mechanical Design & 3D Design Software

- AutoDesk Navisworks® – Project Review (3D) Simulation Software

- AutoDesk Nastran® In-CAD (formally Simulation Mechanical) – CAD Embedded Finite Element Analysis Software

- PneuCalc – Pneumatic Convey Calculation Software

- AFT Fathom

Our Mechanical

Engineering Experience

Featured Mechanical Engineering Projects

Calcium Carbonate Production Plant

AMG provided design-build services for a plant that grinds limestone and produces dry calcium carbonate products for the paint and plastics market.

The large facility utilizes many complex systems, including: compressed air, control system SCADA/HMI, dust collection, flash drying, mechanical conveying, motor controls, particle coating, pneumatic conveying, power distribution, and size reduction.

Spray Dryer Installation

AMG provided detailed engineering, project management, and construction services for the installation of a spray dryer to a facility that utilizes algae fermentation to produce omega-3 fatty acids.

Systems involved included: chiller systems, compressed air, condensate, control system SCADA/HMI, cooling towers, electrical distribution, fermentation, filtration, steam systems, and sterilization/pasteurization systems.

Corn Milling Expansion

In support of plant expansions at a corn milling facility, AMG provided consulting and engineering for the fructose and process areas.

Speciality PVC Resin Production

A manufacturer of proprietary plastics compounds used by OEMs in the automobile industry needed a new production line engineered for specialty resin. AMG provided detailed engineering plans including designs and specs encompassing plastics blending, extrusion, cooling, and more.

Aerosol Packaging Line

A leading producer of adhesive and sealant products for construction and home repair consulted with AMG to support an upgrade to the packaging system in one of its manufacturing plants. AMG provided project management, construction management, and start-up support for an aerosol packaging line upgrade.

Expanding Production Further

AMG provided engineering services for a $25,000,000 expansion at a facility that manufactures amino acids via bacterial fermentation using corn syrup as a feedstock. AMG’s scope encompassed detailed mechanical, structural, electrical, and piping design and engineering, as well as instrumentation specifications and construction supervision.

Relevant systems included: bulk material storage, centrifugation, chiller systems, CIP systems, compressed air, steam and condensate, cooling towers, dewatering, drying, dust collection, evaporation, explosion venting, fermentation, filtration, heat exchange systems, liquid-solid separation, material handling, mechanical conveying, membrane filtration, packaging, pneumatic conveying, power distribution, pumping systems.