The Right Controls

For Your System

Our Instrumentation and

Controls Team’s Strengths

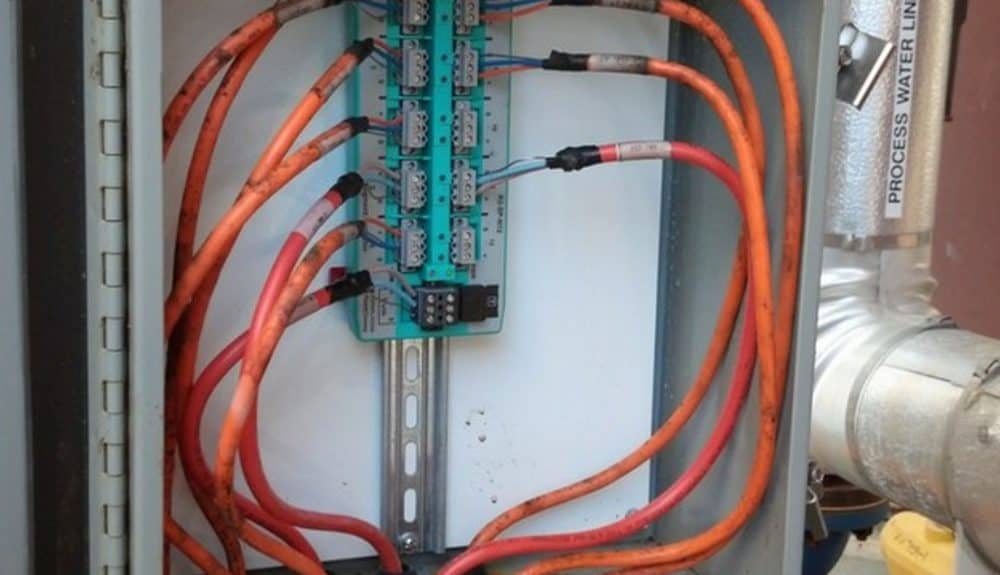

The right combination of process sensors, valves, control systems and programming is fundamental to the success of any industrial manufacturing process. We have the field-experience and technical know-how to support your project.

Our instrument and controls team has a broad background in industrial process automation from machine control such as packaging lines to batch processes such as fermentation media preparation to large continuous processes such as ethanol distillation. Our common sense approach and field experience when combined with our process and piping expertise allow us to solve your process instrumentation and controls problems and make your project a success.

Instrumentation and Control Services

- Complete Instrument Project Engineering, Estimating and Scheduling for new installations and/or modifications of existing systems.

- Upgrading existing control systems from conventional electronic or pneumatic control to Distributed/PLC control, with minimum loss of production.

- Diagnosing, trouble-shooting and verifying fail-safe design of new and/or existing safety systems such as Flame Safety on Lime Kilns and Boilers.

- Logic & Ladder Diagrams

- Motor Elementaries

- Control Panel Layouts

- Control Room Layouts

- Instrumentation Loop Diagrams

- PLC & DCS Configuration

- Programmable Controller Field Wiring Diagrams

- Computer Room Design

- Electrical & Instrumentation Check-out & Start-up

- System Trouble Shooting

- Existing System Documentation

- Feasibility Studies

- Cost Estimating

See Other Core Disciplines

Professional Associations We Belong To

Ready to get Started?

Technology/Software Tools We Use

- SKM Power Tools

- Easy Power

- Revit 3D

- AutoCAD Electrical

- Dranetz 4100 Power platform

- ETAP – ELECTRICAL POWER SYSTEM ANALYSIS

Our Instrumentation

and Control Experience

Featured Instrumentation and Control Projects

Fermentation Expansion Design-Build

An algae fermentation facility in Kentucky utilized AMG’s consulting services to provide complete design-build services for expansions.

The project involved many complex systems including: chiller systems, compressed air, condensate, control system SCADA/HMI, cooling towers, electrical distribution, fermentation, filtration, steam systems, sterilization and pasteurization systems.

Algae Oil Extraction Plant

AMG was contracted to provide design-build services for the construction of an extraction facility in South Carolina that produces specialty nutrients. This large facility utilizes algae fermentation to extract DHA and ARA.

AMG provided detailed engineering and oversight for many complex systems including: centrifugation, compressed air, condensate systems, control system SCADA HMI, distillation and evaporation, power and electrical distribution, explosion venting, material handling, packaging, pneumatic conveying, solvent extraction, and steam systems.

Procurement Support for Distillation Skid

AMG provided procurement and contracted fabrication services for a distillation skid system for a cutting-edge facility that uses fermentation to produce farnesene – a versatile specialty oil ingredient for a wide variety of products including fuel and cosmetics.