We Design

Structural Solutions

Our Structural

Team’s Strengths

We provide practical thinking and cost-effective structural designs to support your operations. We work on projects of all sizes—from sizing a single monorail to designing an entire facility from the ground up.

Our team of structural engineers and designers leverage their “out of the box” creativity to develop and implement cost effective, intuitive, robust solutions for structural challenges. From reinforcing an existing building column, to designing the foundations and steel for a multi story heavy industrial processing building, we have the skill set, knowledge base, and experience to fill your structural needs, large or small.

Whether your project involves a Retrofit or New Construction, Demolition or Expansion, Failure Analysis and Damage Repair or Change in Occupancy, we offer the following services to solve your challenges.

Structural Engineering Services

Concrete/Foundation

Engineering & Design

- Deep Foundations

- Mat/Spread Footings

- Slabs on Grade

- Cast in Place Concrete Structures

- Pre-Cast Concrete Structures

- Post-Tensioned Concrete Structures

- Masonry structures

- Elevated Concrete Slabs

- Tank/Silo/Bin Foundations

- Truck and Rail Unload Pits

Structural Steel

Engineering & Design

- Equipment Support Structures Towers

- Industrial Structures

- Moment Frames

- Braced Frames

- Pipe Bridges

- Personnel bridges

- Material Handling Conveyor Galleries

- Monorail/Hoist Systems

- Rail Unload Pits per AREMA Guidelines

- Truck and Rail Loadout

Architectural

Engineering & Design

- Industrial Building Cladding Systems

- Access and Egress Structures

- Fire Protective Coatings/Systems

- Damage Limiting Construction (Explosion Venting)

See Other Core Disciplines

Professional Associations We Belong To

Ready to get Started?

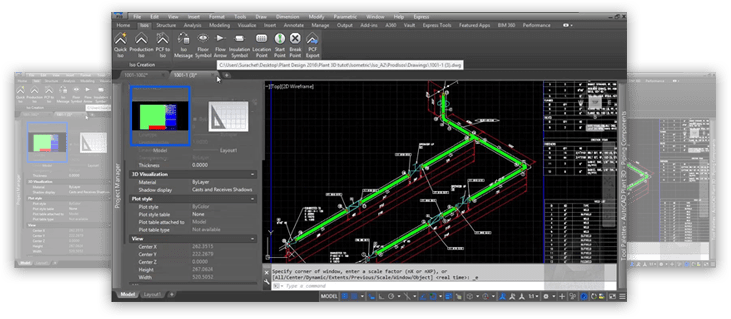

Technology/Software Tools We Use

- AUTODESK Plant 3D

- Multi-Suite Multi-Steel

- Tekla Tools

- Staad-Pro

- safe

- RAM Steel

- L-Pile A

- UTODESK Advanced Steel

- AUTODESK Structural Bridge Design

- AUTODESK Robot Structural Analysis Professional

Our Structural

Engineering Experience

Featured Structural Engineering Projects

Expansion of Enzyme Production Facility

AMG was brought in to provide engineering services to support a $50,000,000 capital expansion at a chemical processing complex that produces specialty enzymes used in the grain processing industry. AMG provided process, mechanical, piping, structural, electrical and controls engineering and design services as well as construction coordination support. The project involved fermentation, compressed air, chillers, cooling towers, steam and condensate, sterile piping systems, and many other systems.

Sugarcane Bagasse to Xylose Sugar Syrup

AMG provided engineering and design for a new demonstration scale plant with a capital value in excess of $80 million. The plant validates a technology that enables extracting highly refined xylose sugars from sugarcane bagasse waste and other cellulosic biomasses.

The project involved the design of many integrated systems, including: biomass dewatering, centrifugation, chemical reactor, chemical storage, chromatographic separation, compressed air, condensate, cooling towers, evaporation, filtration, ion exchange, liquid-solid separation, material handling, milling, steam systems, and wastewater treatment.

Calcium Carbonate Production Plant

AMG provided design-build services for a plant that grinds limestone and produces dry calcium carbonate products for the paint and plastics market.

The large facility utilizes many complex systems, including: compressed air, control system SCADA/HMI, dust collection, flash drying, mechanical conveying, motor controls, particle coating, pneumatic conveying, power distribution, and size reduction.

Corn Milling Expansion

In support of plant expansions at a corn milling facility, AMG provided consulting and engineering for the fructose and process areas.

Speciality PVC Resin Production

A manufacturer of proprietary plastics compounds used by OEMs in the automobile industry needed a new production line engineered for specialty resin. AMG provided detailed engineering plans including designs and specs encompassing plastics blending, extrusion, cooling, and more.

Ethanol from Barley

A contractor that specializes in industrial agricultural markets called upon AMG to support the construction of a large new plant that produces ethanol from barley. AMG provided detailed design and engineering plans as well as site CAD support and consulting throughout the project.

Enzymatic Degumming

AMG provided detailed engineering support for the final phase of an enzymatic degumming project at an oilseeds processing facility in Ohio. AMG provided process, mechanical, piping, structural, and electrical engineering and design as well as construction management services.

Outdoor Storage Construction

AMG provided engineering, procurement, and construction management of four outdoor FX storage tanks at a corn milling facility in Canada that produces corn fructose.